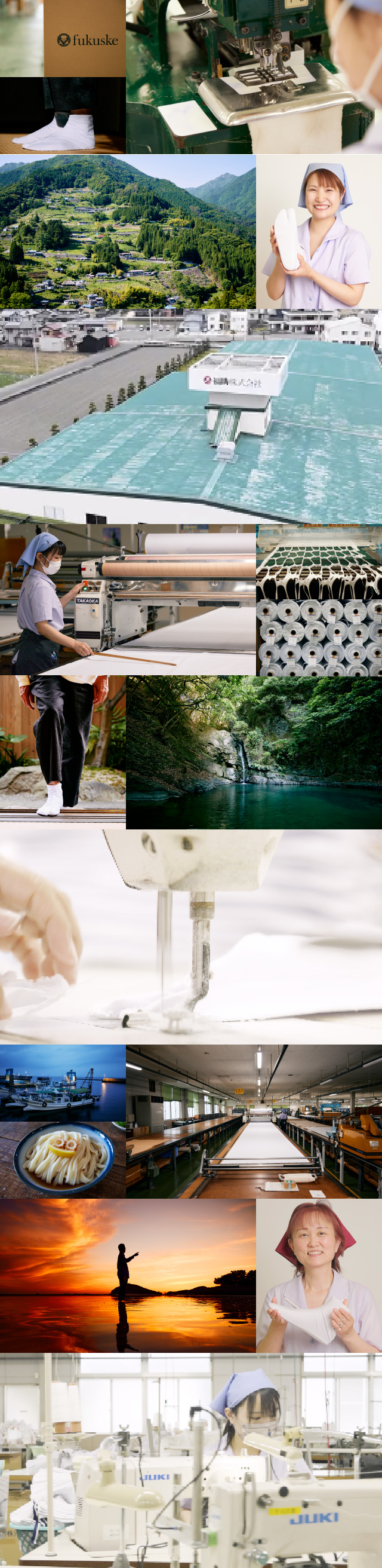

Setouchi

sewing machine concerto

of women sewing tabi

A journey to meet growth stories

Shikoku Fukuske Co., Ltd.

THE STORIES #004

Shikoku Fukuske Co., Ltd.

THE STORIES #004

- 1st movementGet to know Tabi

- second movementsew together

Women's growth story - KakushoKannonji TempleSightseeing spots around Daisan

Deeper than you can imagine

Tabi making technology

Fukuske was founded in 1882 as a tabi clothing store. At the time, hand-sewing was the norm, but we developed machine-sewn technology for tabi. Each stitch to sew tabi socks is packed with advanced technology and history that cannot be imitated by others.

More complicated than it looks!

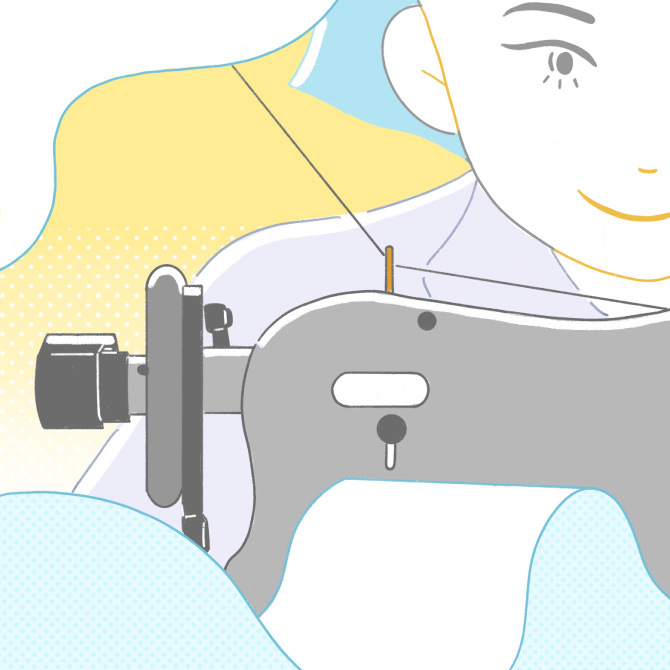

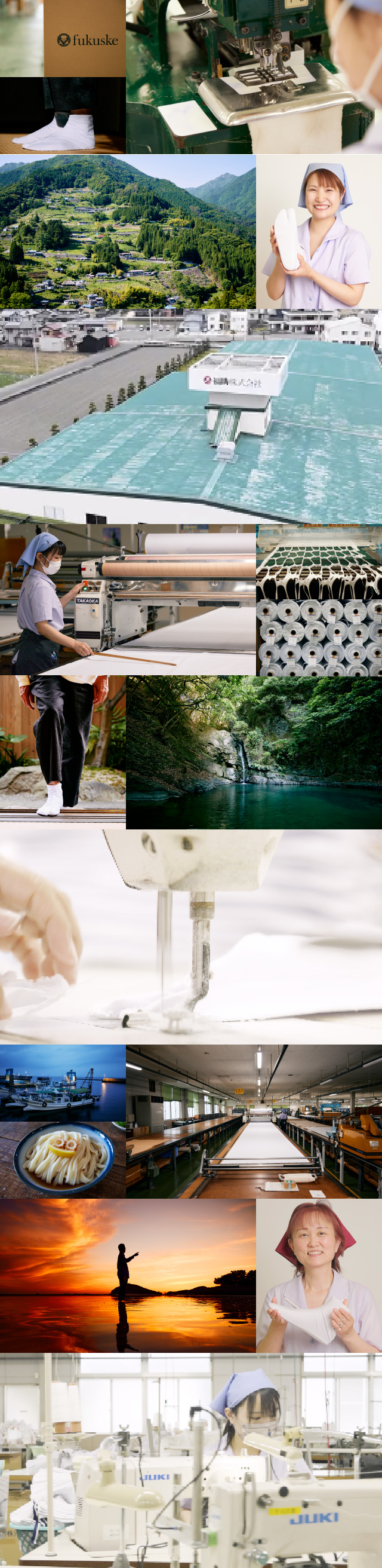

To sew or not to sew. For parts that require complicated sewing, we use our own special sewing machine.

The quality of fabric and stitching is top priority!

If there is even the slightest mistake or inadequacy, mercilessly redo it. No compromise is the basis of quality.

This roundness is craftsmanship!

The curve of the toe that comfortably wraps around the fingertips is one of the most advanced techniques in making tabi.

Preparation before sewing is the key

color matching

We strictly check the condition and color of the purchased fabric one by one.

fabric pull

Layer the fabric while straightening it so that it is easy to cut.

Cutting

The pattern is applied in an exquisite arrangement that does not leave excess fabric, and it is cut at once.

“Once you have all the parts, it’s time to sew!”

through a number of processes

A pair of tabi is sewn

- 01Through

- 02back trowel

- 03Hagi next

- 04entanglement

- 05presser foot

- 06rush

- 07rush

- 08ground stitching

- 09standing armor

- 10side return

- 11wind stop

- 12round stop

- 13Appetizer

- 14Around

- 15Entanglement

- 16finish

- 17iron

Through

Tabi parts are divided into five parts: the inner shell on the thumb side, the outer shell on the other four sides (each with a front and back), and the bottom. After cutting each part, the first thing to do in the sewing process is to thread the thread to hang the kohaze (fastener for the tabi). Fukuske's own special machine is used, and when you step on the pedal, the needle penetrates the fabric at once, and the thread is threaded. When the needle is pulled out, the thread is automatically cut, and it only takes a few seconds to thread two threads!

back trowel

The process of making a crease on the part where the goby is attached. You can set it in the machine and crease two sheets at the same time.

Hagi next

If the fabric used is thick, the overlapping parts of the fabric will become thicker, which may affect the comfort of the shoe. In that case, put a thin piece of dough on one part and make sure that the overall thickness is not too thick.

entanglement

Using a pattern sewing machine, firmly reinforce the area between the thumb and index finger (the part called the crotch).

presser foot

Sew a presser stitch so that the thread that was threaded in step 1 does not come off. If you sew all over the thread, you won't be able to hook the goby, so the point is to avoid the part where the thread is exposed by a few millimeters. Attention is the small "wing" attached to the presser part of the sewing machine. This feather pushes the threads well and sews only the appropriate parts. However, the most amazing thing is the craftsmanship that manipulates it! A sewing machine that runs at high speed is controlled with a subtle amount of force.

rush

There are several types of kohaze, and the order of the kohaze used differs depending on the breed of tabi. In some cases, the size and type of fabric are written on it, and it actually functions like a quality display tag. The process of quickly identifying such goby and arranging them correctly according to the breed, size, and right and left direction of the tabi is the process. If you make a mistake in the order of even one, you will have to start over. It is different from just arranging, and instant judgment is required.

rush

If the material is stretchy or stretchy, it won't be firmly fixed even if you attach the goby as usual, and it will pop up. In order to hold it down, sew the presser stitch again from the top.

ground stitching

Jisugi is the process of sewing together the outer and lining fabrics of the tabi. The four toe side of the instep is sewn inside out, and the thumb side of the instep is sewn inside out and then turned inside out (jigaeshi). After setting the thumb side fabric in the four finger side fabric, proceed to the next step.

standing armor

Sew together the front and back 4 pieces of fabric set in step 8 at once at the instep. It is the part that you can see from the front when you put it on, so the beauty of the seams is important. It is also the part where the most force is applied when wearing it, so strength is also necessary. The sewing machine used here has been remodeled so that when the switch is pressed with the knee, the stitches become smaller. Press the switch when you reach the point where you want to add strength, and sew tightly and finely. The craftsmanship that achieves a certain curve and strength shines.

side return

When the thumb side fabric and the four finger side are sewn together, turn the fabric inside out.

wind stop

When you put on the tabi and put it on, the fabric on the side of the seam hanging thread will be stretched if it is made of stretchy material.

round stop

After stitching together the thumb side and the four toe side of the instep with a standing instep, before attaching the sole, make a ring shape and sew the overlapping part of the heel together in a circle. At that time, carefully check the small notch mark called "Giza" attached to the fabric and sew it in the correct position. If this is misaligned, it will cause excess or shortage of dough in the subsequent process of attaching the bottom.

Appetizer

An important process to realize the beauty and ease of wearing of Fukuske tabi is the process of creating the exquisite swelling of the toes. While making exquisite gathers according to the curve, the fabric is adjusted and sewn so that it fits perfectly. With both a special sewing machine and skilled skills, the bulging and beautiful curves are completed for the first time. It takes time and effort, so the number of people involved is the largest, and we spend time teaching young people for the purpose of inheriting the tradition.

Around

After finishing up to the tip, sew the bottom and integrate all the parts. It doesn't matter if you run out of dough or have some left over. While looking at the condition of each tabi, he instantly decides whether to pull the fabric slightly or to sew it with a slight push, and sews together while making exquisite adjustments.

Entanglement

It wraps around the bottom to reinforce it so it doesn't fray.

finish

The sewn socks are turned inside out, so use a wooden stick to turn them inside out. The snap of the neck and the beautiful return to the toes are truly craftsmanship! After that, the tabi is tightly sandwiched between Fukuske's unique wooden molds. In the past, finishing was hard work done by hitting with a wooden mallet. The Fukuske style, where women do the finishing process, surprises other companies.

iron

After finishing, check the stitching and seam alignment once, and after confirming that there are no problems, proceed to the final ironing process. It is sandwiched in a special press machine that matches the shape of the tabi, and the wrinkles of the tabi that have gone through 16 processes are smoothed out. Once this is done, the bag is carefully put into a bag by hand, passed through a needle detector, and ready for shipment! Japan's top quality tabi will be delivered to us.

be sewn together

Women's growth story

Four women working at Shikoku Fukuske. What is their growth through making tabi?

Once you decide

It's early!

Mr. Umemoto

feeling to challenge

Was born

Miki

while being supported

to the leader

Mr. Doi

than anyone else

I was competitive

Mr. Shirakawa

changing times and

Making unchanging tabi

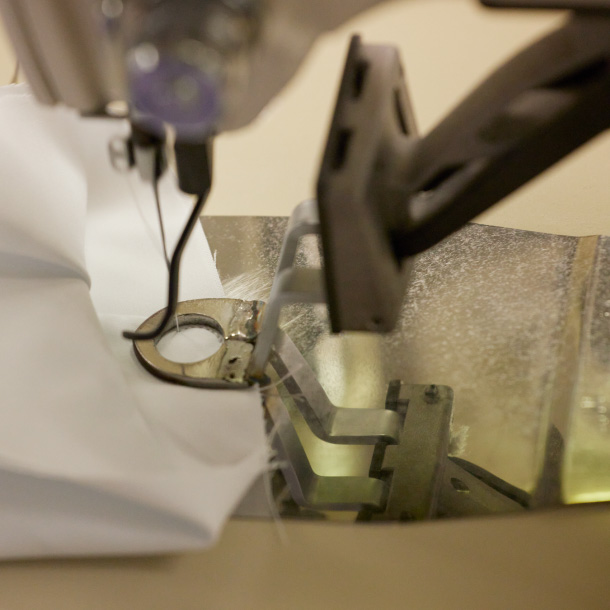

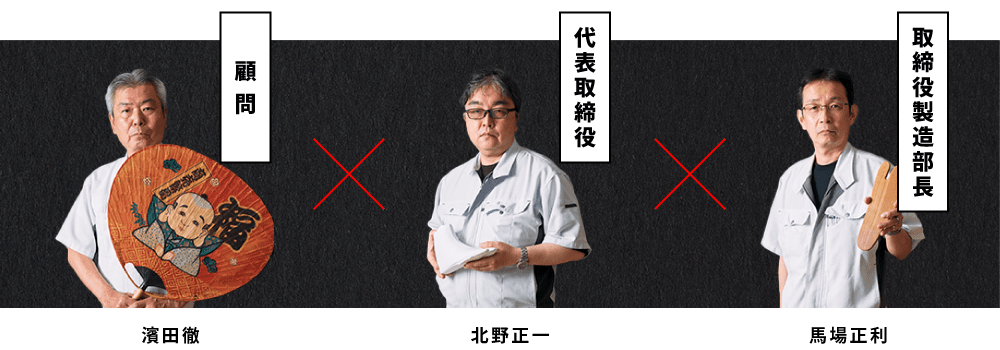

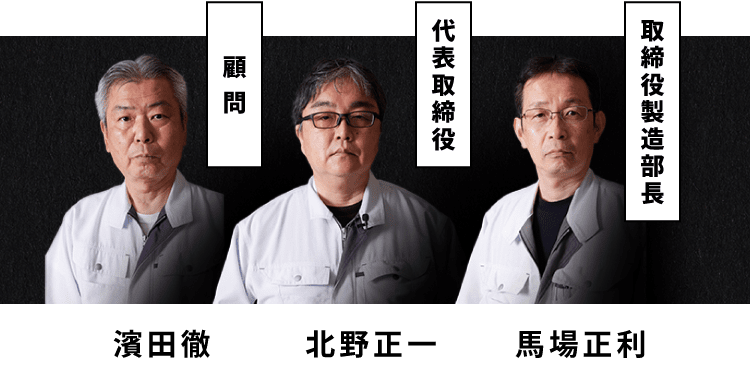

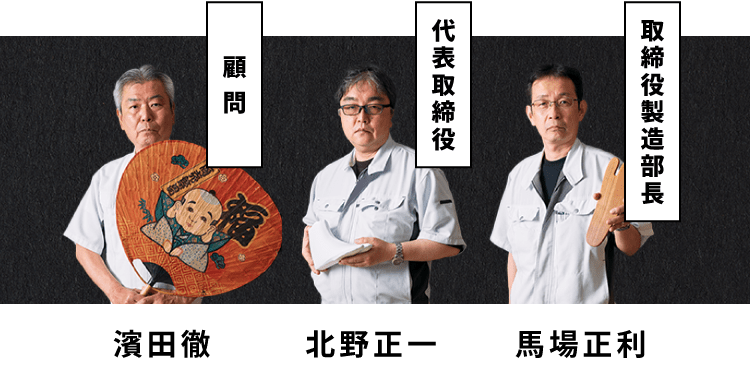

The three people who run the Shikoku Fukusuke factory will talk about passing on the tradition of making tabi socks and training young workers.

There is meaning in not changing

Fukusuke's tabi making is faithful to the basics. Where to hold the fabric, where to put it, how to sew. They are all determined to make good tabi, and the same teaching method has been passed down for decades.

They are also very strict about quality. The number of suppliers that meet Fukusuke's quality standards is limited, and there are only a few, including companies that have been doing business with Fukusuke for over 100 years. It is said that "if it works for Fukusuke, it works for others."

The factory and the people are very neat. Before I became a permanent resident at Kanonji, I worked in Tokyo. It's not dusty at all for working with textiles. It may be that the company culture that is faithful to basics and quality is reflected.

Having worked at the Shikoku Factory for more than 30 years, I took it for granted, but almost everyone who visits the factory is impressed by how our tabi are made. It wasn't until someone told me about it that I realized for the first time how amazing the unchanging craftsmanship is.

Even so, the times are changing

Fukusuke went through civil rehabilitation in 2003. Amidst the chaos at the head office, I was suddenly asked to go to the Shikoku factory, even though I had never been directly involved in tabi manufacturing. Since this is a manufacturing site, the impact was relatively small, but even so, we needed to make changes as a factory, such as being required to further improve efficiency.

Nonetheless, we had already established a sophisticated production process with no waste, so we didn't change the way we made it. Other parts changed. But mentally, I felt uneasy about the employees. Kanonji is a large company with a long history of familiarity, but at that time, I think everyone had the awareness that it was not natural for them to continue.

It's not a job that anyone can do

I mentioned that Fukusuke's tabi making is faithful to the basics, but that doesn't mean that anyone can do it. Above all, you need concentration and compatibility. In some cases, a new employee who is not good at speaking to the point of worrying as a member of society has grown to the point of surpassing the veteran in just a few months.

Depending on the process, there are suitability and unsuitability, and there are many cases where if a person who does not progress easily is transferred to another process, their progress suddenly progresses. On the other hand, there are all-rounders who can skillfully handle any process. We believe that it is our role to find a process that suits each person while carefully observing the performance of each person.

A few years ago, the baby boomer generation retired at once, and the age group has dropped a lot. I think it's the same for all companies that hiring young people is getting harder year by year, but Fukusuke takes pride in supporting the kimono culture. I would like to create a mechanism that can appeal to a wider range of people with our pride and our history.

There are many other attractions!

If you go to Shikoku Fukusuke

Please visit and feel it!

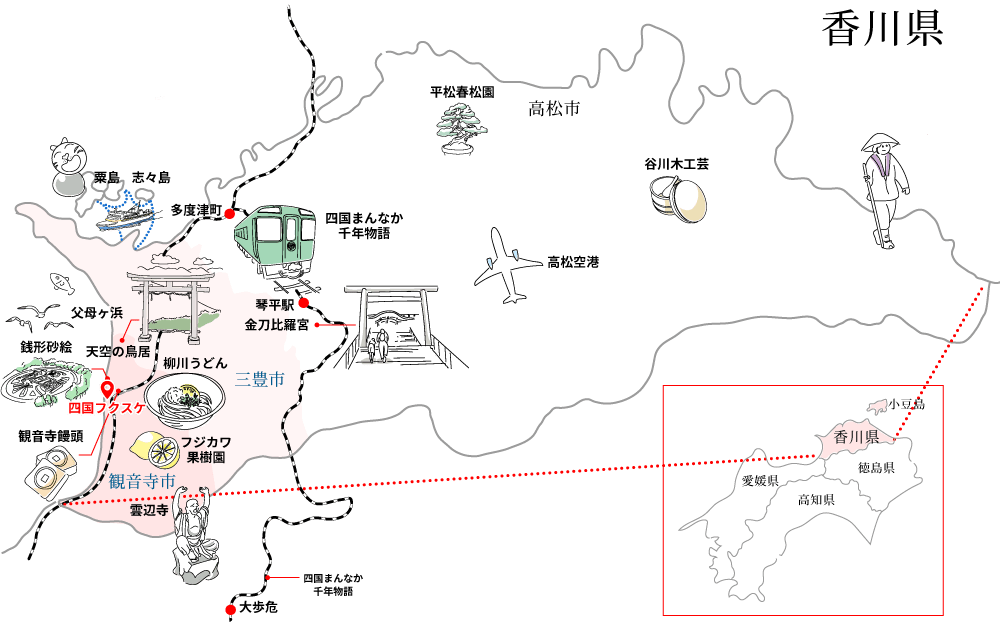

Kannonji Temple and Surrounding Area of charm

sightseeing

map

Street snap @ Kagawa Prefecture

people in guesthouse

boat taxi driver

Udon shop people

Owner of dried sardine ramen

bucket workers

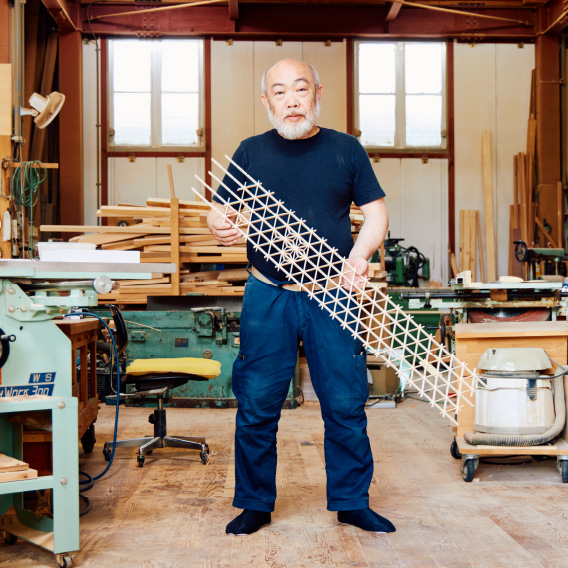

traditional craftsman

Mikan and lemon farmers

Bonsai masters

A man who greeted me in the rice field in front of the factory

Women making tabi socks in Shikoku Fukusuke

The Toyotsu Group should be proud

There are traditional techniques andcraftsmanship.

Shikoku Fukusuke has been supporting Fukusuke's and Japan's traditions for decades.

Even when we were forced to shorten working hours due to the effects of the new coronavirus, we always kept the factory running for a few hours a day and never stopped the work of the craftsmen. This is to ensure that the traditional skills that have been handed down will not be dulled even for a moment.

We hope that what we have measures for reinforcing our business foundation here will serve as a bond between people and between companies, and become a source of inspiration and inspiration for creating something new.